|

| April 05, 2016 | Volume 12 Issue 13 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

The advantages of using edge-bonded shims

By Christie Jones, Market Development Manager, SPIROL International Corp.

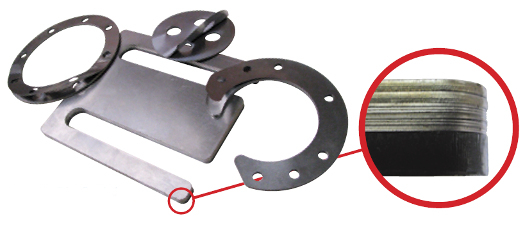

Precision shims often have profiles that match the mating components of the assembly.

Precision shims are used as compensators to absorb tolerances between mating components. They significantly reduce manufacturing costs by eliminating the need for each component to be precision machined in order to achieve the proper fit and function of the total assembly. During the assembly process, shims provide adjustment to compensate for accumulated tolerances that significantly reduces the need for re-machining and assembly time. Additionally, shims are commonly used to preserve the faces between mating components, cutting down the required machining time during rebuilds/retrofitting.

At SPIROL, we offer precision shims in a variety of materials, including carbon steel, stainless steel, aluminum, brass, and copper. Each material offers specific benefits for our customers' specific applications, including corrosion resistance, wear resistance, and more, making them ideal in many industries.

Typical applications include:

- Pumps and motors, motor support struts, thrust reversers, fuselage, landing gears, gas turbines;

- Hydraulic controls, refrigeration, and industrial ventilation machines;

- Injection molding, extrusion, printing, paper machinery;

- Machine tools;

- Automotive, aircraft, and aerospace markets;

- Agricultural equipment; and

- Civil engineering equipment.

Laminated shims have peelable layers of metal that are removed until the shim has the proper thickness. They are built up from layers of precision-gauge metal foil. Layers are bonded into a rigid structure that appear and function as a solid sheet or plate. Adjusting them is as easy as peeling off laminations with a knife, or in the case of some materials, using no tool at all.

Rather than having to stack a number of individual shims, a single shim set can be adjusted to the desired thickness and slipped into position. In this way, variable close tolerances can be achieved, saving considerable time required to pick various different thicknesses of loose shims. This provides cost savings by reducing assembly time and also minimizes line-side SKUs and related inventory storage space. The finished laminated shims withstand reasonable handling, including shearing and machining.

In addition to being fully laminated, laminated shims can also be partially solid and partially laminated. This type of shim is either half-solid or three-quarter solid, depending on the ratio of solid section to total thickness. Semi-solid shims add rigidity to a design by meeting the performance requirements of a thicker, solid shim. They provide a bearing surface on one side, yet they allow adjustments to the overall thickness of the shim by enabling the user to peel off unwanted layers from the other side.

SURFACE-BONDED LAMINATED SHIMS

Surface-bonded laminated shim packs, simply referred to in the industry as "laminated shims," are adhered throughout the entire surface between each layer of material, and the layers are pressed together to cure, similar to how plywood is manufactured. The unwanted layers must be discarded due to their deformation during peeling.

Surface-bonded laminated shims must be adjusted using a tool.

Unwanted layer deformation of surface-bonded laminated shims.

EDGE-BONDED SHIMS

The layers of an edge-bonded shim set are first pressed together, and then adhered by only the edges of the shim's profile. This allows for a much easier separation of the layers in the field. Since edge-bonded shim sets are easy to peel, the layers that are not needed are preserved and can be used for a later application.

Edge-bonded shim sets have all the performance and cost advantages of solid and loose shims, yet they provide a unique solution for companies seeking a better point-of-use, adjustable shim set. Another advantage of edge-bonded shims is that multiple lamination thicknesses can be combined in the same stack, giving the customer more flexibility for adjustment. This is not an option for traditional laminated shims.

Semi-solid edge-bonded shims allow course and fine adjustments to thickness.

Edge-bonded shims also provide cost-saving advantages over conventional laminated shims because the materials are less expensive. Edge-bonded shim packs offer safe adjustment in seconds, and are much easier to peel than surface-bonded laminates. Safety is improved, because no knife is needed to remove the edge-bonded layers. Cost savings can also be realized, because the layers that are removed from the edge-bonded shim pack are reusable, functional parts, since no deformation of the layers occurs during adjustment.

CONCLUSION

Both types of laminated shims (surface bonded and edge bonded), offer the advantages of reducing assembly time, taking up less inventory storage space and reducing the number of line-side SKUs. However, when speed of adjustment, operator safety, and minimizing your overall cost of assembly are your primary objectives, edge-bonded shims provide the best solution.

Learn more at www.spirolshims.com.

Published May 2016

Rate this article

View our terms of use and privacy policy